Mezzanines are a superb way to maximise space and efficiency at work, however, they can also pose a hazard when it comes to health and safety. Find out about the legislation that applies to mezzanine safety, as well as the guidelines that should be followed to ensure that any staff, visitors, or customers using a mezzanine stay safe and secure at all times.

The Health & Safety at Work Act

Originally devised in 1974, The Health & Safety at Work Act is a crucial piece of legislation that targets ongoing high standards of health and safety for employees and visitors in the workplace by ensuring that businesses abide by standardised criteria.

It is an employer’s responsibility to ensure the standards of health and safety are kept to. Therefore, if employees or visitors were to regularly use an installed mezzanine within their facility, it is of utmost importance that employers uphold, and if required update, health and safety standards on the structure, in order to solidify ongoing mezzanine safety.

This is to the company’s benefit as well, because having a safe environment permits continued productivity as employees can perform their tasks with no obstructions relating to their safety in the workplace. It also reduces the risks of potential lawsuits, because it is less likely that an incident will occur within the facility.

A Health & Safety Inspector’s Expectation

When a Health & Safety Inspector visits to assess your performance, they will want three important questions answered in order for your workplace to successfully pass inspection.

- What procedures are in place to avoid accidents?

- What standard of health and safety training do employees receive?

- What procedures are in place if an incident was to occur?

Our Advice

Mezzanine Health & Safety Guidelines

To maintain effective mezzanine safety, there are a number of practices that can be put into place across a business. Mezzanine safety should be a concern for both the management team and the employees, so the most important thing is to make sure that everyone is aware of the potential dangers, and about their responsibilities.

It’s a Collective Effort

It is not all down to the employer. Indeed, it is their responsibility to implement guidelines, ensure they are being upheld, and regularly review and monitor potential risks, but it is also the employee’s task to make a concerted effort to abide by these guidelines and raise concerns if an issue were to arise.

Give Employees More Responsibility

For employers, it is good practice to appoint Health and Safety Officers amongst employees. These can be the go-to individuals within departments or organisations when it comes to guideline revisions or possible issues. This generates health and safety awareness, and is a successful method of establishing regular communication and reviews of health and safety practices.

Understand the Capabilities of Your Mezzanine and Wider Facility

One of the most important considerations when it comes to mezzanine safety should be the nature of your premises, and the capabilities of the mezzanine itself.

Weight Load Threshold and Safe Ground Bearing Pressure

It’s imperative that you understand the point load capabilities of your mezzanine structure. Without this vital piece of information, you will not know the maximum weight capacity of the mezzanine. This would considerably increase the risk of overbearing the structure.

Likewise, it is important that you have knowledge of the safe ground bearing pressure of the site’s slab and foundations. This should have been considered when designing the supporting column grid of the mezzanine structure, and therefore already taken into account when stating the point load of the mezzanine. However, it is still beneficial to have a complete understanding of your environment and it may come in handy if you wish to adapt your mezzanine in the future.

The Weight of Your Items

It is also important that you know the weight of the items you are placing on your mezzanine. How are you supposed to keep to the mezzanine’s point load if you do not know the weight of the items you are placing onto it?

Install suitable Protective Measures for Mezzanine Safety

The features attached to the mezzanine are just as important as the structure itself. Without these, the mezzanine floor wouldn’t be fit-for-purpose or safe to use. So, it is essential that you acquire suitable features that meet your requirements.

Finished Floor Type

Do not overlook the importance of the material you are standing on. This is a key part of any construction and you need to identify what you require from your floor; if you have chosen incorrectly this may affect productivity and could even be a health risk.

Ask the following questions when checking if your current floor is suitable, or if you are considering a refurbishment.

- What are the loading requirements of the floor?

- Should the floor possess an anti-slip surface?

- Do I require the floor to have reduced deflection?

- Will it have to bear repetitive movement?

- Should it be water-resistant or waterproof?

- Will it need to have sound-proof qualities?

Edge Protection

If there are open edges to your structure, you will require edge protection measures to guard against potential injuries or worse. Is a simple railing provision system enough, or will you require mesh protection as well?

Staircases

The importance of safe and fast movement of personnel between floors is an often-undervalued aspect of a mezzanine structure. The speed and ease of movement across a facility directly affects productivity, and it is no different when an employee wishes to move up and down its floors on staircases.

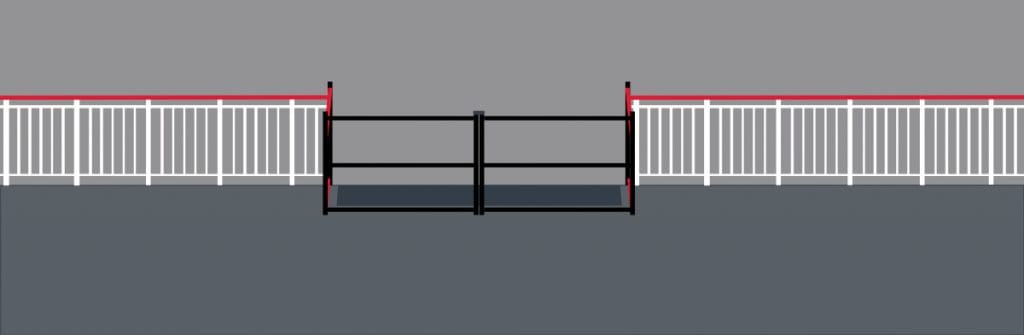

Pallet Gates

Pallet gates are a simple and effective method of permitting fast and safe movement of heavy goods between floor levels. When not in use, they successfully protect users with a swinging barrier that can be easily placed into the closed position, aligning with the surrounding edge protection and creating a complete barrier. Able to take different pallet sizes, it is a cheaper and more efficient method of transporting pallets from a forklift, as opposed to installing a goods lift.

Keep Access and Walkways Clutter-Free

Stairs and walkways are an integral aspect of mezzanine safety. It is crucial that these are always accessible and straightforward to navigate. It is good practice to train all employees to be aware of obstructions. It could be one of the tasks of an appointed Health and Safety Officer to keep areas free of obstruction.

Regularly Review Fire and Safety Guidelines & Perform Risk Assessments

As your business, staff and processes evolve, the standard and fire safety guidelines do as well. So, even after construction, a proven approach to ensure ongoing compliance would be to regularly review these guidelines and assess if the risk precautions are suitable. This could be another responsibility held by one of the health and safety officers within the organisation.

Top Tips Summary

- Ensure you can answer the three fundamental questions any health and safety inspector would ask

- Give employees more responsibility when it comes to the company’s health and safety standards

- Know the point load of your mezzanine

- Know the safe ground bearing pressure of your site’s slab and foundations

- Know the weight of the items you are placing on your mezzanine

- Ensure your mezzanine’s features (floor type, edge protection, staircases and pallet gates) are fit-for-purpose

- Keep stairs and walkways clear and obstruction-free

- Regularly review standards and fire safety guidelines

- Regularly perform risk assessments

Achieving Mezzanine Safety: The Hi-Level Solution

Raising the Standard

The mission of Hi-Level has remained true throughout the company’s 29-year history – to provide value-engineered, future-proof mezzanine solutions that meet each of our partners’ requirements and to keep people who are working at height safe. With our numerous quality and safety accreditations, we successfully keep to this aim with every mezzanine project we undertake.

High Standard Products

Finished Floor Type

Hi-Level provides a large collection of bespoke flooring options which meet a diverse set of requirements.

Edge Protection

With custom powder coated railing and steel kickplates provided as standard, Hi-Level offer one of the best edge protection systems on the market.

Staircases

Hi-Level provide flexible staircase solutions suitable for various requirements. With different sizes and finishes, we can offer safe and fast movement between floors to a plethora of industries.

Pallet Gates

Much like our edge protection, Hi-Level offer powder coated pallet gates which possess strong gloss retention.

Learn more about achieving compliance with UK building regulations, in order to keep employees safe while they operate on mezzanines.