A warehouse’s layout after the initial moving in process is often never changed throughout the facility’s use. This commonly overlooked aspect directly affects a site’s daily logistical process and, perhaps if not adapted, a business’ efficiency over time cannot truly be maximised.

Mezzanine floors are a fantastic method of expanding your floor space without having to move premises. Even after being installed, these structures can be adapted to meet further requirements and can enable future growth and logistical development.

Why is it important to always have an optimised system in place?

With the ever-increasing expectation of fast delivery, it is crucial that all areas of a business are made to be as time-efficient as possible, especially when it comes to production, sortation and distribution.

If delivery speeds are deemed too slow compared to others within the industry, the likelihood of losing potential business is considerably higher.

Aspects of Improvement

Effectively Organising Stock

- Arrange stock by popularity – If there are some products which are ordered consistently more than others, make sure to put those at the most accessible areas on your mezzanine or ground floor. Having these readily accessible means that they can be sent to customers quickly.

- Inventory control – It’s surprisingly easy to lose track of stock levels and order the incorrect amount of produce. Ensure to regularly keep track of stock and monitor any consumer ordering trends. It may be beneficial to look through previous years to try and gauge consumer habits during different times of the year.

- Keep it clutter-free – Keeping walkways and shelves clutter-free is a simple and quickfire method of providing a safe and time-efficient logistical process within any warehouse premises.

Educate Staff and Clearly Signal Areas

It is a must that every employee with regular contact with your warehouse(s) understands the layout and function of your premises. This is more for safety reasons, but it will improve time-efficiency; as if a person understands the fastest routes, they can get to their destinations faster. Installing clear signs around the warehouse will also help with this.

Transporting Goods from Mezzanine to Ground Floor Quickly and Safely

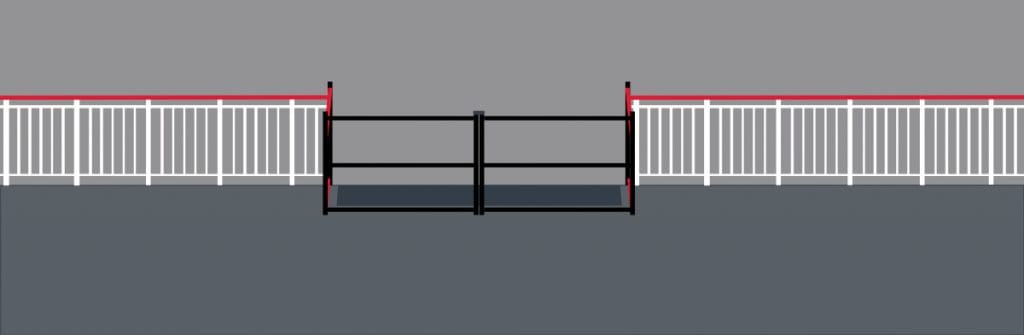

Another key aspect of improving time-efficiency within warehouses which involve a mezzanine is to identify the quickest method of transporting goods from (and to) the structure. One method is to install a goods lift, this automated system can run 24/7 and, depending on the type, is capable of withstanding significant weight loads. However, it is a costly method which demands certain square footage of your premises. The more cost-effective method would be to install a pallet gate solution, this system permits simple, safe and fast transportation of goods across floors and will require pallet trucks. As this is significantly cheaper, you can install several of these across the mezzanine; enabling faster product transportation across the structure.

Be Prepared to Adapt Workspaces

It’s important to regularly analyse the efficiency of both your manual workstations and automated systems, especially when there is a mezzanine structure as part of the facility’s layout. Mezzanines are built to be adaptable, which makes the installation of new equipment or automated processes a much simpler operation.

Is There Enough Space for a Mezzanine Extension or New Structure?

One way to surefire guarantee a warehouse is optimised is to use the maximum square footage possible. If there is still unused overhead space after the installation of a mezzanine there is still potential for further workstations or storage areas.

Mezzanines can be installed around live operation, so if either an extension, additional floor or new structure is required, an installation team can erect the build with minimal disruption to regular business operations.

An Optimised Environment Should Always be Safe

There is no substitute for a safe working environment. The most crucial element of enabling continued operations is to ensure the working environment permits the safe completion of tasks. One example of this is to have a sufficient understanding of your mezzanine’s capabilities. For example, its maximum weight load; knowing this will mean the risk of overstoring your mezzanine (and possible collapse) is eradicated.

Find out more information on mezzanine safety here.