Buying a mezzanine is an important purchase with many potential benefits for your business. It is good to have reliable information at your fingertips to avoid common misconceptions about what is and isn’t possible. With our simple guide you can get to grips with the essentials of mezzanine magic and make informed decisions.

Here we bust the mezzanine myths.

Mezzanine floors can only be installed in new builds

One of the most common mezzanine misconceptions is that mezzanine floors can only be fitted into new buildings. In fact, mezzanines are frequently retro-fitted into existing premises as companies expand, seek productivity benefits and look to the future. A well-designed mezzanine can transform an underused area into valuable operational space – without the need for relocation or costly construction work.

Hi-Level Mezzanines specialises in bespoke systems that integrate seamlessly within occupied or older premises. Each structure is engineered to the building’s layout, load-bearing capacity and intended use, ensuring safety and compliance at every stage. Whether the goal is to expand storage, create new office areas or accommodate automation equipment, Hi-Level’s engineers design solutions that work around existing columns, lighting and racking layouts.

Installing a mezzanine within an operational facility offers significant advantages: minimal disruption, rapid installation and return on investment. By using the vertical space already available, businesses can increase capacity without extending their footprint or committing to a full redevelopment project.

FACT, NOT FICTION:

Mezzanine floors are one of the most practical and adaptable ways to expand an existing site – not something limited to new builds.

Installing a mezzanine would mean a huge amount of downtime

Another common mezzanine misconception is that installation will bring business operations to a halt. In reality, a professionally managed mezzanine project can be completed with minimal disruption – often while the facility remains fully operational.

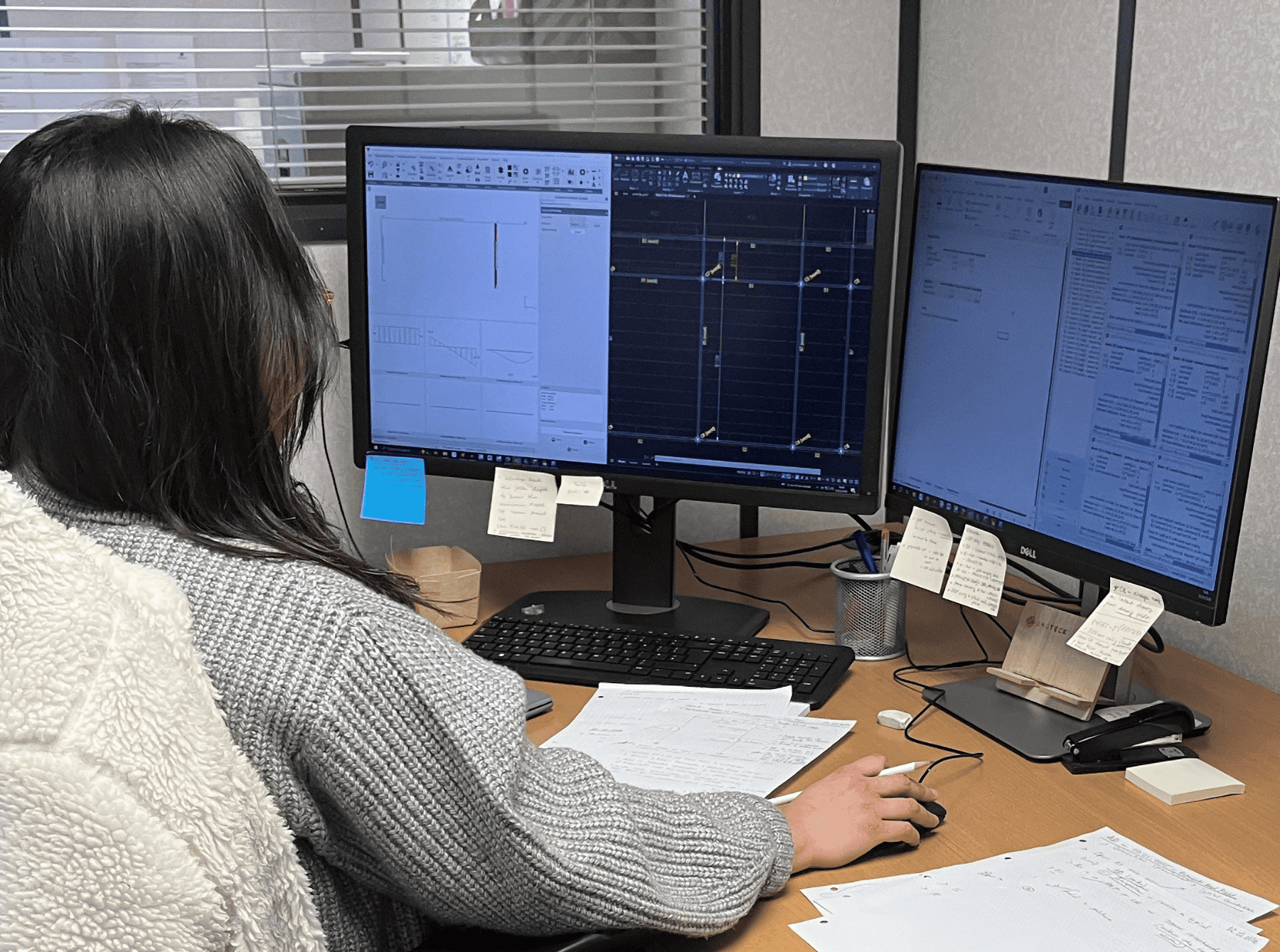

At Hi-Level Mezzanines, every project is carefully planned around the client’s schedule to keep productivity on track. Detailed site surveys and digital design modelling allow the team to understand site constraints in advance and plan installation phases that minimise interference. Where possible, work can be scheduled outside of peak operating hours, during evenings or weekends, to further reduce impact.

Hi-Level’s in-house project management ensures smooth coordination from design through to installation. Components are precision-engineered in the UK and delivered to site ready for rapid assembly, reducing time spent on-site. Clear communication between the project team and client ensures that safety and efficiency are prioritised at all times.

FACT, NOT FICTION:

Mezzanines are expensive

It’s easy to assume that a mezzanine floor represents a costly investment – but this is one of the most common mezzanine misconceptions. When compared to alternatives such as relocation, leasing additional premises or extending a building, mezzanines offer a far more cost-effective way to gain valuable space.

Hi-Level Mezzanines applies a value-engineered approach to every project, ensuring that materials are used efficiently without compromising safety or quality. Each structure is designed specifically for its intended use, which means clients only pay for what they need – not for unnecessary capacity or features. By manufacturing in the UK and managing the entire process in-house, Hi-Level controls costs and timelines from start to finish.

A mezzanine can also deliver a strong return on investment. The additional floor area it creates can be used for storage, production, office space or automation systems, often increasing operational capacity by up to 100% without expanding the site footprint.

When viewed over its lifetime, a mezzanine is an asset that continues to add value year after year.

FACT, NOT FICTION:

Mezzanine floors are one of the most economical ways to expand – providing long-term value without the expense of moving or rebuilding.

Mezzanines are only for warehouses

A widely held mezzanine misconception is that mezzanine floors are suited only to warehouses. While they are a popular choice in logistics and storage, mezzanines are incredibly versatile and used across a wide range of environments – from offices and retail stores to manufacturing facilities, showrooms and even public spaces.

Hi-Level Mezzanines designs bespoke structures to suit each client’s space and purpose. In retail, a mezzanine might provide additional display or stock areas; in offices, it can create extra workspace or meeting rooms without the need for relocation. In production or distribution settings, mezzanines can support automation systems, conveyors or technical equipment.

Because Hi-Level’s designs are entirely custom-built, they can be finished to match the look and function of any environment – from high-spec commercial interiors to heavy-duty industrial operations. Ancillary products such as staircases, safety barriers and the Hi-Tile robot-ready flooring system ensure both practicality and professional presentation.

By transforming underused vertical space, mezzanines help businesses in all sectors make more efficient use of their buildings.

FACT, NOT FICTION:

Mezzanines are far more than warehouse solutions – they’re adaptable, multi-purpose structures designed to enhance virtually any type of commercial or industrial space.

Mezzanines are only for storage

Another frequent mezzanine misconception is that mezzanine floors serve a single purpose – storage. While many businesses do use them to increase storage capacity, their potential extends far beyond shelving and stock. Modern mezzanines are highly adaptable structures that can support a wide variety of uses, from offices and break areas to production lines, showrooms or automation systems.

At Hi-Level Mezzanines, each project is designed around the client’s objectives. In a warehouse, a mezzanine might create a new packing area or fulfilment zone; in a retail environment, it could provide additional floor space for displays; and in a manufacturing plant, it can house machinery or technical equipment safely above ground level.

With advanced design and engineering, mezzanines can support heavy loads, integrate with building services and meet all relevant fire and safety standards. Hi-Level’s automation-ready designs and Hi-Tile flooring system make our mezzanines particularly well suited to modern production and logistics settings where efficiency is essential.

By unlocking the potential of overhead space, businesses can expand their operations without increasing their footprint.

FACT, NOT FICTION:

Mezzanines are flexible, multi-purpose structures – ideal for storage, offices, production or any other activity where space is at a premium.

Mezzanines can only be one level

A common mezzanine misconception is that mezzanine floors are restricted to a single level. In reality, multi-tier mezzanines are a highly effective way to multiply usable floor space, particularly in tall buildings where vertical capacity is underused.

Hi-Level Mezzanines has extensive experience designing and installing multi-tier systems for large-scale commercial and industrial projects. These structures can span two, three or even more levels, each engineered to handle the specific load requirements of its intended use, whether that is storage, automation, production or office space. By integrating staircases, pallet gates, lifts and safety barriers, Hi-Level ensures full accessibility and compliance across every tier.

Multi-level mezzanines are especially valuable in logistics and fulfilment centres, where maximising cubic space directly translates to higher efficiency and lower operating costs. They are also ideal for sectors such as e-commerce, automotive and manufacturing, where growth demands additional capacity without expanding the site footprint.

Hi-Level’s turnkey service, from structural engineering to installation, ensures that each level is precisely aligned and built to last.

FACT, NOT FICTION:

Mezzanines are not limited to one floor. They can rise multiple levels high, creating stacked layers of productivity within the same footprint.

Mezzanines for robotics mean a big financial outlay all at once

Many businesses hesitate to invest in automation-ready mezzanines because they believe it requires a large, immediate capital outlay. This mezzanine misconception overlooks how modern mezzanine design and project planning can make automation integration far more flexible and financially manageable.

Hi-Level Mezzanines engineers its structures with the future in mind. A mezzanine can be installed in stages. You can start with a robust base platform that supports current operations, then adapt later for conveyors, robotics or automated storage systems as the business grows. This phased approach allows companies to spread costs over time while still preparing their facility for future automation.

Hi-Level’s Hi-Tile flooring system is designed to accommodate heavy loads and precise robotics movement, meaning there is no need for costly rework when automation is introduced. With careful planning and value-engineered design, clients can futureproof their investment while maintaining budget control.

FACT, NOT FICTION:

Automation-ready mezzanines are an investment that can be scaled and phased, offering long-term value without a single large upfront cost.

Installing a mezzanine is very disruptive

A frequent mezzanine misconception is that installation will cause major disruption to day-to-day operations. In reality, mezzanine projects can be completed efficiently and safely while your business continues to operate, provided the work is planned and managed by an experienced team.

At Hi-Level Mezzanines, every project begins with a detailed site survey and comprehensive installation plan. This allows the team to sequence the build around the client’s operations, maintaining safe access routes and minimising downtime. Where possible, work can be scheduled outside normal operating hours or completed in carefully managed phases to keep workflows uninterrupted.

Because all steelwork is precision-engineered in the UK and delivered ready for assembly, on-site construction is streamlined and predictable. Hi-Level’s experienced installers work closely with site managers to maintain safety, coordination and efficiency throughout the project.

The result is a fast, well-organised installation that delivers maximum benefit with minimal disruption. For most clients, the process is quicker and less intrusive than expected.

FACT, NOT FICTION:

Installing a mezzanine does not have to disrupt your business. With professional planning and coordination, Hi-Level ensures your project runs smoothly from start to finish.

Mezzanines do not need planning permission, building regulations compliance or fire-rating

A potentially risky mezzanine misconception is that these structures can be installed without planning permission, building regulation approval or fire safety measures. In truth, mezzanine floors are classified as structural additions. This means they must comply fully with UK building regulations to ensure safety, stability and accessibility.

At Hi-Level Mezzanines, every project is designed, calculated and certified to meet all relevant standards. This includes structural integrity (Part A), fire protection (Part B), accessibility (Part M), and health and safety requirements. Our qualified structural engineers provide all the necessary calculations and drawings to support regulatory approval, giving clients complete peace of mind.

While planning permission is rarely required, it can be necessary if the mezzanine significantly alters a building’s appearance, use or fire strategy. Hi-Level’s experienced team advises clients at every stage, liaising with local authorities or approved inspectors when needed.

You may need planning permission if any of the following apply:

- External changes: the mezzanine involves external alterations such as new windows, doors, staircases, loading platforms or extensions.

- Retail premises: planning permission is required if the mezzanine increases the total retail floorspace by more than 200 m² (as per the Town and Country Planning (General Permitted Development) Order 2015).

- Change of use: if the mezzanine changes the use of the building (for example, from storage to office or public access), planning may be needed.

- Listed buildings / Conservation Areas: any internal works affecting the character of a listed building require listed building consent, even if they are internal only.

- Fire or building control constraints: while separate from planning, Building Regulations approval is always required, regardless of size or use.

Fire safety is also a crucial consideration. Depending on the size and use of the mezzanine, features such as fire-rated ceilings, protected staircases and emergency lighting may be needed. If the mezzanine is small and used for light storage only, fire protection often not required. If it is large, occupied or forms an extra floor level, full 60-minute fire protection will be needed.

FACT, NOT FICTION:

Mezzanine floors must always meet building regulations and fire standards. Hi-Level ensures every installation is fully compliant and safe to use.

Mezzanines always look boring, grey and industrial

One of the more outdated mezzanine misconceptions is that mezzanine floors are purely functional, with a dull, industrial appearance. While that may have been true decades ago, today’s mezzanines can be designed to complement any environment from sleek corporate offices to high-end retail spaces.

At Hi-Level Mezzanines, every structure is bespoke and can be customised with finishes that reflect a company’s brand and surroundings. Powder-coated steelwork can be supplied in virtually any colour, while flooring options such as Hi-Tile, carpet or composite panels provide both strength and aesthetic appeal. Handrails, staircases and safety barriers can also be designed to suit the look and feel of the space, whether that’s contemporary and minimalist or robust and industrial.

Hi-Level regularly works with architects, interior designers and brand managers to ensure the finished installation enhances the visual identity of the building. The result is a space that feels cohesive, professional and entirely in keeping with its environment, from your brand colours to a sleek office look.

FACT, NOT FICTION:

Mezzanines don’t have to look grey or utilitarian. One client asked for bright colours and a funky café to recruit new employees to its factory. We delivered just what was wanted.

All mezzanines are the same, so just compare £/m²

A common mezzanine misconception is that all mezzanine floors are broadly identical, making price per square metre the only factor worth comparing. In reality, two structures may look similar on paper but differ greatly in quality, performance and long-term value.

At Hi-Level Mezzanines, every project is engineered to the client’s exact requirements taking into account load capacity, building layout, usage type and integration with other systems such as automation or material handling. The quality of design, steel specification, fire protection and installation standards all have a direct impact on safety, lifespan and regulatory compliance.

A low-cost option may appear attractive initially but can lead to higher maintenance costs, limited adaptability or even the need for replacement if not designed correctly. Hi-Level’s value-engineered approach ensures optimal use of materials and budget without compromising on strength or compliance.

When assessing suppliers, it is vital to look beyond headline figures. Consider the expertise, safety record and future-proofing that come with a trusted manufacturer.

FACT, NOT FICTION:

Mezzanines are not all the same. True value lies in quality engineering, compliance and design excellence, not just in the £/m² price tag.

A mezzanine only adds space

It is easy to think that a mezzanine floor’s sole benefit is extra square footage, but that is one of the biggest mezzanine misconceptions. In reality, a well-designed mezzanine can do far more than create additional space. It can improve workflow, efficiency and the overall functionality of a building.

At Hi-Level Mezzanines, every structure is engineered to enhance how a facility operates. In a warehouse, a mezzanine might separate storage from packing or create a dedicated area for automation and robotics. In offices or production environments, it can support new departments, streamline movement between processes or even reduce travel distances within the building.

By making better use of vertical space, a mezzanine can also support future growth, allowing businesses to adapt layouts as operations evolve. Mezzanine floors add efficiency, organisation and long-term flexibility, not just square metres.

FACT, NOT FICTION:

A mezzanine is a strategic investment that enhances productivity, supports expansion, and transforms the way businesses use their space – well beyond simply adding more of it.

Any flooring will work on top of a mezzanine

A frequent mezzanine misconception is that any standard flooring can be laid on top of a mezzanine structure. In fact, the flooring is one of the most important design considerations. It directly affects load capacity, fire safety, acoustics and the performance of any machinery or equipment installed above.

At Hi-Level Mezzanines, the flooring specification is carefully matched to the intended use of the space. For example, offices or retail areas may require lightweight, noise-reducing surfaces, while industrial or automation environments demand high-strength materials capable of withstanding heavy loads and precise robotic movement.

Hi-Level’s proprietary Hi-Tile flooring system is robot-ready, using robust interlocking 7mm textured PVC tiles to create the most durable, cost-effective flooring on the market. Its seamless interlocking joints, electrostatic resistance and anti-slip surface make it the perfect partner to robotics solutions. It is also proving popular in a wide range of other applications.

Using unsuitable flooring can lead to deflection, vibration or even non-compliance with building regulations.

FACT, NOT FICTION:

The right flooring is critical to mezzanine performance. Hi-Level’s engineered solutions ensure your mezzanine floor is safe, durable and built to handle the demands of your operation.

Mezzanines cannot take heavy weights

Another widespread mezzanine misconception is that mezzanine floors are only suitable for light use such as offices or storage and cannot support heavy machinery or equipment. In reality, mezzanines are structural steel platforms that can be designed to handle substantial loads, provided they are engineered correctly.

At Hi-Level Mezzanines, every project begins with detailed structural calculations based on the client’s operational requirements. This includes the weight of stored goods, machinery, racking systems or automation equipment. Load capacities can be tailored to accommodate anything from light shelving to multi-tonne manufacturing lines, with the supporting columns and beams sized accordingly.

Hi-Level’s team of qualified structural engineers ensures each design complies fully with British Standards and building regulations. For clients in sectors such as automotive, logistics or production, mezzanines are often specified to carry dynamic loads, conveyors and even robotics. All are tested for safety and stability.

Choosing a supplier with proven structural expertise is essential, as poor design can compromise performance or safety.

FACT, NOT FICTION:

Mezzanines can be built to support exceptionally heavy weights. Hi-Level’s engineered steel structures deliver the strength and reliability required for demanding industrial environments.

Any warehouse slab can take a mezzanine and you can put columns wherever you like

A potentially costly mezzanine misconception is that any warehouse floor can support a mezzanine and that columns can be positioned anywhere. In reality, the strength and design of the existing concrete slab play a critical role in determining how and where a mezzanine can be safely installed.

At Hi-Level Mezzanines, every project begins with a thorough structural survey to assess the load-bearing capacity of the floor. Factors such as slab thickness, concrete strength and sub-base conditions must be verified to ensure the structure can safely support the additional weight of the mezzanine, its contents and any live loads such as people or machinery.

Column placement also requires careful planning. Random positioning could interfere with racking, workflow or access routes. Hi-Level’s engineers use advanced modelling to optimise column grids, balancing load distribution with operational efficiency. Where slab capacity is limited, they can design bespoke solutions such as larger base plates or load-spreading foundations.

Professional design ensures both safety and functionality from the outset.

FACT, NOT FICTION:

Not every slab is mezzanine-ready, and columns must be strategically placed. Hi-Level’s expert engineering ensures every design is structurally sound and suited to your specific site conditions.

Talk to us about how a mezzanine can transform your business.